Briquettes for volume reduction and heat energy production.

Craft enterprises and industrial operations produce wood chips shavings and saw dust on

a daily basis that take up considerable space to store and transport. By contrast, briquettes

save space and are easier to transport, and unlike loose materials, present a far lower risk

of spontaneous combustion. Briquetting presses from VOTECS process these wood chips,

shavings etc. into compact briquettes that can be used to produce energy for heating. The

briquetting presses are installed as a standalone machine or in conjunction with evacuation

systems. The advantages of the briquettes produced by these machines are a huge reduction

in volume for the same heating value and controlled combustion.

The characteristics of VOTECS briquetting presses are:

Briquetting –Large volumes made small

The material to be compressed is mixed by a continually turning tube extractor in the container and then fed to the pressing mechanism by a discharge screw conveyor. The loose material is then subsequently pre-compressed. Then pressed by the press cylinder, the pre-formed briquette is transformed into its final, highly compacted form. When the defining pressure value is reached, the tongs open and the briquette is pushed out.

Thought-out construction

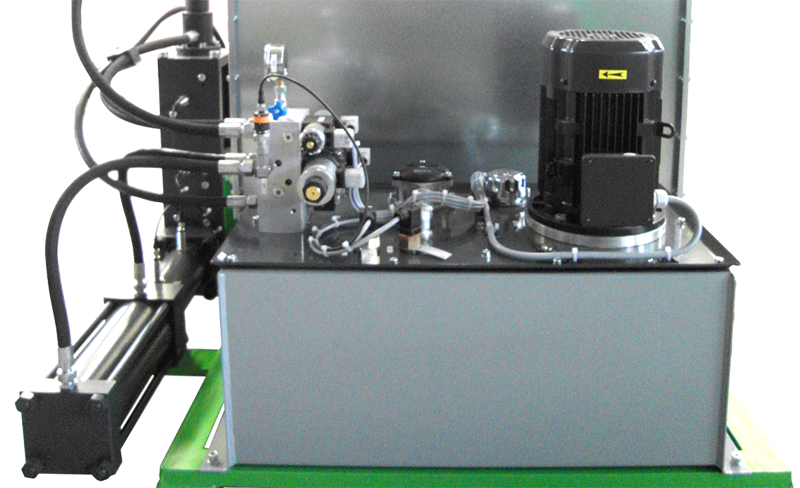

The hydraulic tank is arranged separately. In this way, the emerging oil heat is optimally discharged. Easy access makes the regular maintenance service pleasant and efficient.